Please read and understand these instructions completely before proceeding with the instal-lation of the EZ-Set Torsion Spring SystemTM. Carefully follow these instructions to avoid personal …

How to Install EZ SET Torsion Springs on a garage door

In this video, we'll show you how to install an EZ-SET Torsion Spring on your garage door. Learn more at https://www.clopaydoor.com/residentia....

Single EZ-SET Torsion Spring Replacement - DDM Garage Doors

Detailed step-by-step instructions for safely replacing Clopay's and Ideal's -EZ-SET torsion springs.

Clopay EZ-SET Assembly/Installation Instructions - ManualsLib

View and Download Clopay EZ-SET assembly/installation instructions online. Torsion Spring System. EZ-SET garage door opener pdf manual download.

How to install ez set torsion spring system?

Sep 16, 2024 · We hope this guide has provided you with a comprehensive understanding of how to install an EZ Set torsion spring system. Remember, safety is paramount when working with …

EZ Set Torsion A - clopaydoor.com

How to safely install Clopay overhead garage door EZ Set Torsion Springs. Part 1 of 4.

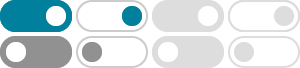

Push the two torsion tube sections firmly into the coupler. in each end of the coupler. When attaching the coupler to each tube be sure to use the two holes that are on the same side of …

DIY Master: How to Replace Ideal EZ Set Torsion Springs

Oct 3, 2025 · Following these detailed steps will ensure a safe, proper replacement of Ideal EZ Set torsion springs, restoring your garage door’s smooth and balanced operation.

To avoid personal injury, do not rest hand or any other part of your body on the spring or any part of the EZ-SET Torsion Spring System while tensioning or untensioning the spring.

Clopay EZ-Set Torsion Conversion Kit for 9 ft. x 7 ft. Garage Doors …

Attach the tube retainer to the EZ-SET® Torsion Spring System bracket with a 3/8" - 16 x 3/4" carriage bolt. Be sure to position the carriage bolt and flange nut as shown in Fig. 14.